What are the ovens for sublimation printing on aluminum and steel?

News

Sublimation printing is a type of decoration characterized by the transfer of effects onto materials, such as pre-painted aluminum, using heat-sensitive inks.

Unlike traditional printing methods, sublimatic ink at about 190°C changes from a solid state to a gaseous state, binding directly to the surface of the substrate. This results in durable, high-definition images that are resistant to aging and outdoor exposure.

- What is Sublimation

- The role of sublimation ovens

- Otefal Sublimation Plants

- Advances in Sublimation Technology

- Sublimation Printing in Architecture

What is Sublimation

Sublimation is a physicochemical process that allows the transfer of ink from a sublimation medium (such as paper) to another material (such as pre-painted aluminum) using heat. The process is divided into two stages: first, the design is printed on a special transfer support (paper or polyester film); then, the printed film obtained is wrapped around the profile to be decorated, adhered to it through a vacuum, and finally brought to temperature using a specific sublimation plant.

This method allows for the creation of qualitative and lasting decorations on various types of supports and materials.

The role of sublimation ovens

At the heart of this process is the sublimation oven, which evenly distributes the high temperatures necessary for the ink to sublimate and transfer onto the surface of the previously painted metal. Modern sublimation ovens are designed with precise temperature control, ensuring consistent quality across all products. They cater to a wide range of products and sizes, profiles, and flat surfaces, for both indoor and outdoor use.

Otefal Sublimation Plants

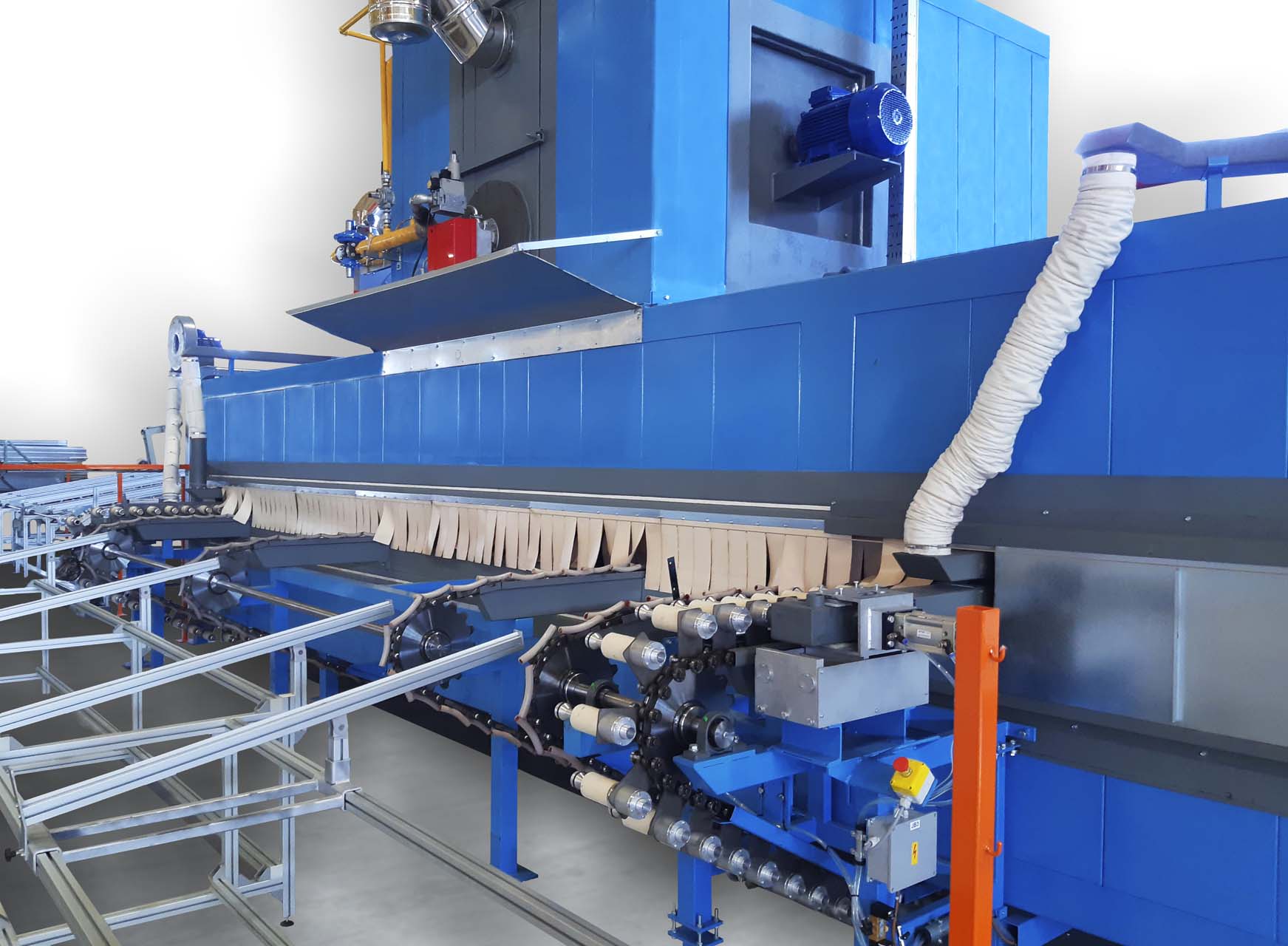

Otefal’s sublimation plants (presses and ovens) for aluminum and steel are advanced tools designed for the decoration of metallic surfaces through sublimation. Through temperature, these ovens allow the pigments in the film to sublimate and then bond to the previously painted metallic surface, transferring the motifs and colors. Otefal Engineering designs automatic and semi-automatic ovens, adaptable to the specific production needs of individual clients.

Oven Models:

- Automatic Oven – Sublifast/OT-ASP Series

- Semi-Automatic Drawer Oven – Sublinova/OT-DSP Series

- Manual Trolley Oven – Free Card/OT-TSP Series

- Sublimation Presses – OT-P Series

Advances in Sublimation Technology

Recent advances have significantly improved the efficiency and quality of sublimation printing on aluminum. Innovations include better heat distribution, faster processing times, and more sustainable operational processes. Additionally, the integration of digital technology has expanded design possibilities, allowing for more complex and detailed images.

Environmental Impact

Compared to traditional decoration methods, sublimation printing is extremely eco-friendly, using less energy and being completely water-free. Regarding sublimation plants, the prerogative of new models is the constant reduction of energy consumption.

Practical Applications

Aluminum decorated through sublimation finds applications in various architectural sectors, from windows and doors to facades and furniture accessories. This versatility stems from the durability and aesthetic quality of sublimated products, which can withstand external environmental conditions over time.

Sublimation Printing in Architecture

In the construction and architecture sector, sublimation technology revolutionizes the way we approach design and functionality. This method allows architects and designers to apply complex motifs and vivid colors directly to the aluminum panels used in facades, decorative elements, and interior finishes. The durability and weather resistance of sublimated aluminum makes it the ideal choice for both external and internal applications, combining aesthetic appeal and long-lasting performance.

As sustainability and customization are key elements in the sector, sublimation printing represents a viable solution for innovative architectural projects.

Economic and Market Implications

For companies, switching to sublimation printing for decorating aluminum can also be economically advantageous. Although the initial installation costs may be high, the efficiency, product quality, and customization potential can lead to a strong return on investment. This technology also enables small businesses to compete by offering unique, high-quality products without the need for significant production investments.

The Future of Aluminum Decoration

The future of aluminum decoration with sublimation printing will likely see further technological innovations. These may include advances in ink chemistry for even more durable and vibrant finishes, automation to simplify production processes, and integration with digital and 3D printing technologies to create new effects and functionalities.

The continuous development of sublimation printing technology reflects a broader trend toward customization, sustainability, and production efficiency. As both businesses and consumers continually seek products that combine aesthetics with environmental responsibility, sublimation printing is the right solution that meets all these needs.

Do you need more information about our sublimation ovens and sublimation presses? Contact Us.

Request information

Do you need information?

Do you need more information about our sublimation ovens and presses? Are you already one of our customers and need post-sales support? Do you want to talk to one of our qualified team members for technical advice? We are here to help you!